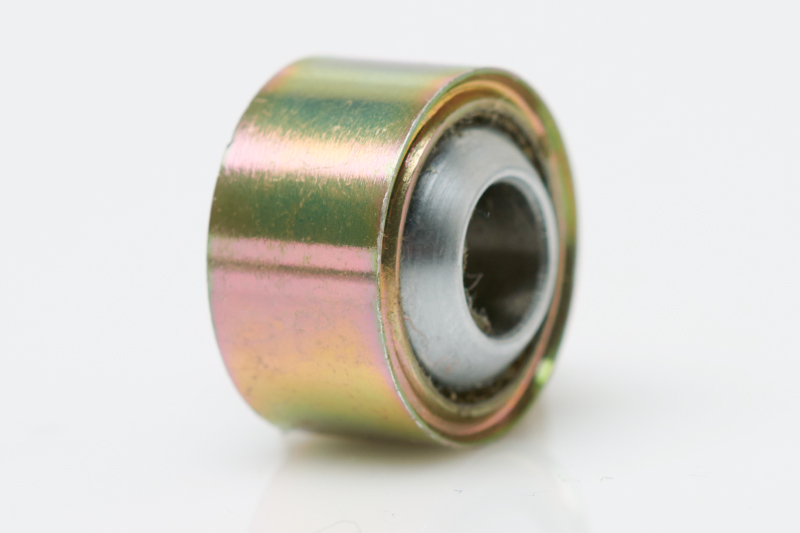

Spherical Bearings

Product Overview

Spherical bearings, also known as bushings or ball bushings, allow for smooth rotation and limited angular motion between components under varying loads. These bearings are used in systems where misalignment and motion occur simultaneously, often under heavy forces or in compact assemblies.

Radial Bearing offers both self-lubricating polytetrafluoroethylene (PTFE) fabric lined bearings and metal-to-metal spherical bearings, designed to meet the needs of aerospace, defense, and advanced industrial systems. Our bearings are available in a range of sizes, tolerances, and material configurations, supported by AS9100D and ISO 9001-certified quality systems.

Product Types

Self-Lubricating Polytetrafluoroethylene (PTFE) Fabric Lined

Metal-to-Metal Bearings

Designed for high-load environments where temperature extremes, vibration, or shock loading may occur. Lubrication grooves and holes at 180° provide a ready means of re-lubrication after installation. Engineered for strength and longevity in rugged conditions. Various metals can be substituted for special applications.

Molded Race, Self-Lubricating, Loader Slot Design

Custom

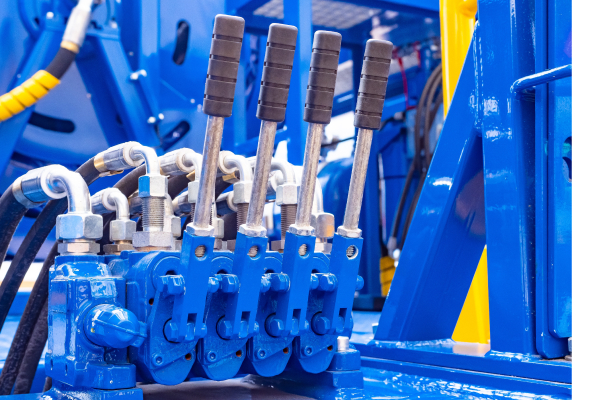

Applications

Our spherical bearings are used in mechanical systems where precision rotation and misalignment must be accommodated under heavy loads or environmental stress.

Common applications include:

Wing pivots and tail assemblies

(yaw bearing systems)

Flaps, rudders, and elevators

Landing gear joints and struts

Helicopter rotor assemblies

Jet and turbine engine pivots

Actuators and motion control systems

Suspension pivots and steering assemblies

Structural hinges and rotating joints

Construction, ag, and on-road vehicle linkages

Industries

- Commercial and Regional Aircraft

- Business and General Aviation Aircraft

- Rotorcraft

- Military Aircraft, Rotorcraft and UAVs

- Ground Vehicles

- Space Launch Vehicles

- Engine Turbo Systems

- Heavy Truck and Suspension Systems

- Specialty Vehicles

- Earth Moving Equipment

- Tractors, Combines, Hay Balers

- Utility Vehicles

- High-performance Racing

- Specialty Manufacturing

- Industrial Systems

Explore Applications Across Industries

Case Studies

Powered by Cablecraft

Leveraging the recognition, credibility, resources and industry expertise of Cablecraft, Radial Bearing is a leading designer and manufacturer of engineered motion control linkage products.

Learn More at Cablecraft.com

Get Started with Radial Bearing

Put reliable control in the hands of the world’s drivers, pilots, and equipment operators with the expertise and support of Radial Bearing. Contact us today to discuss your needs.